Tungaloy Corporation announces the expansion of its TungCut series with the introduction of two new grades: the highly wear-resistant AH8005 and the highly fracture-resistant AH6235.

Grooving and parting operations are indispensable processes in the manufacturing of general machinery and automotive components. However, these operations often involve demanding cutting conditions such as intermittent profiles or long overhangs, which can lead to challenges in tool life and machining stability.

In today’s market, where productivity and cost optimization are essential, further improvement in tool performance has become critical. To meet these demands, the introduction of new cutting tool grades that provide longer tool life and stable machining is highly anticipated. TungCut is a grooving and parting tool with excellent chip control and a highly rigid clamping structure. It achieves high-quality finishing and is suitable for a wide range of machining. It combines stable accuracy with a long tool life.

Benefits and Features

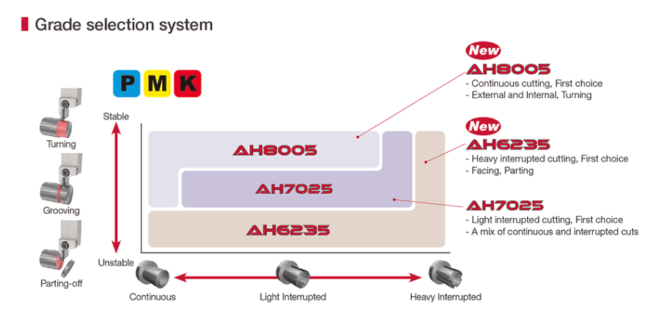

Feature 1: AH8005 – Wear-resistant grade ideal for high-speed and continuous machining

– Suitable for a wide range of workpiece materials including heat-resistant alloys, stainless steel, and general steel

– Exhibits excellent wear resistance even at high temperatures, significantly extending tool life

– Delivers stable cutting performance in continuous and high-speed machining operations

Feature 2: AH6235 – Tough grade for interrupted and heavy-duty cutting

– Designed to handle interrupted cuts and parting operations where chipping and breakage are common

– High toughness reduces the risk of tool failure, enabling stable machining

– Offers outstanding reliability even when machining difficult-to-cut materials such as stainless steel

With the addition of these grades, TungCut can now accommodate a wider range of machining conditions and workpiece materials, contributing to improved productivity and cost reduction in manufacturing environments.

COMMENTS