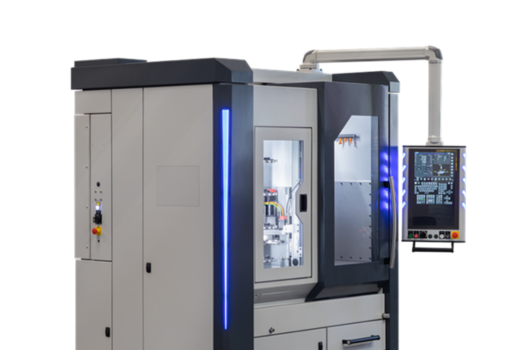

EMISSA SA, part of the Swiss PIBOMULTI group, has announced the launch of its new PreciMill 5X machining center, designed for high-precision applications in watchmaking, micromechanics, connectors, and medtech. The compact machine combines precision, performance, and reliability, reflecting EMISSA’s 80 years of expertise in custom machining solutions. The PreciMill 5X will be showcased at EMO 2025 in Hannover, from September 22 to 26, at Hall 4, Booth E46, with experts available to demonstrate the machine and discuss tailored solutions.

Compact Design, Maximum Performance

Occupying less than 2.25 m², the PreciMill 5X features a rigid ribbed cast iron frame, dynamic axes with linear and direct-drive torque motors, and thermally regulated components for exceptional precision and repeatability. Travel dimensions of 180 x 140 x 160 mm allow machining of parts up to 120 mm³.

The machine includes a 100-position tool magazine with a double-gripper changer, enabling tool-to-tool change in 2.6 seconds and chip-to-chip change in 3.8 seconds. Optional RFID technology enhances tool management. The high-frequency spindle with HSK-E25 holder reaches up to 50,000 rpm and includes high-pressure coolant through the tool, a stop block for turning tools, and a thermal expansion sensor for accuracy.

Advanced Capabilities and Automation

The PreciMill 5X supports simultaneous 4th and 5th axes (B and C), with the C-axis functioning as a turning spindle up to 4,500 rpm. Optional robotic loading and unloading ensures long autonomous operation, reducing production costs. EMISSA also provides custom clamping systems tailored to specific parts and machining operations.

The machine emphasizes accessibility and simplified maintenance, using high-end components and minimizing wear parts. Notably, it avoids ball screws, reducing upkeep while maintaining high performance.

Innovation for Sustainable Machining

PreciMill 5X is pre-equipped for supercritical CO₂ machining, a modern cooling and lubrication method that enhances energy efficiency, tool life, and machining quality.

COMMENTS